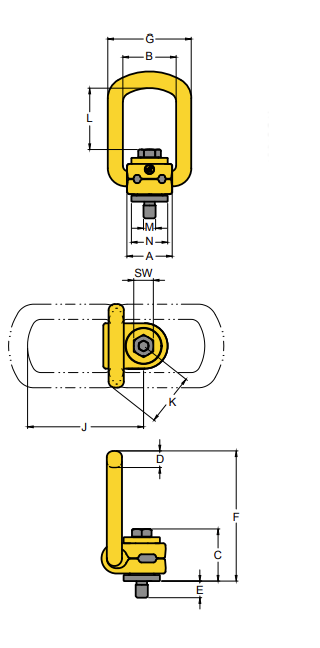

Rotates through 360° and pivot 90°.

Manufactured from alloy steel, quenched and tempered.

Load rated parts are 100% magnaflux crack detected.

Individual forged parts and cap screw are traceable to Test Certification.

Bolts are Metric thread (ASME / ANSI B18.3.1M), specification is grade 12.9 alloy socket head screw per DIN EN ISO 4762.

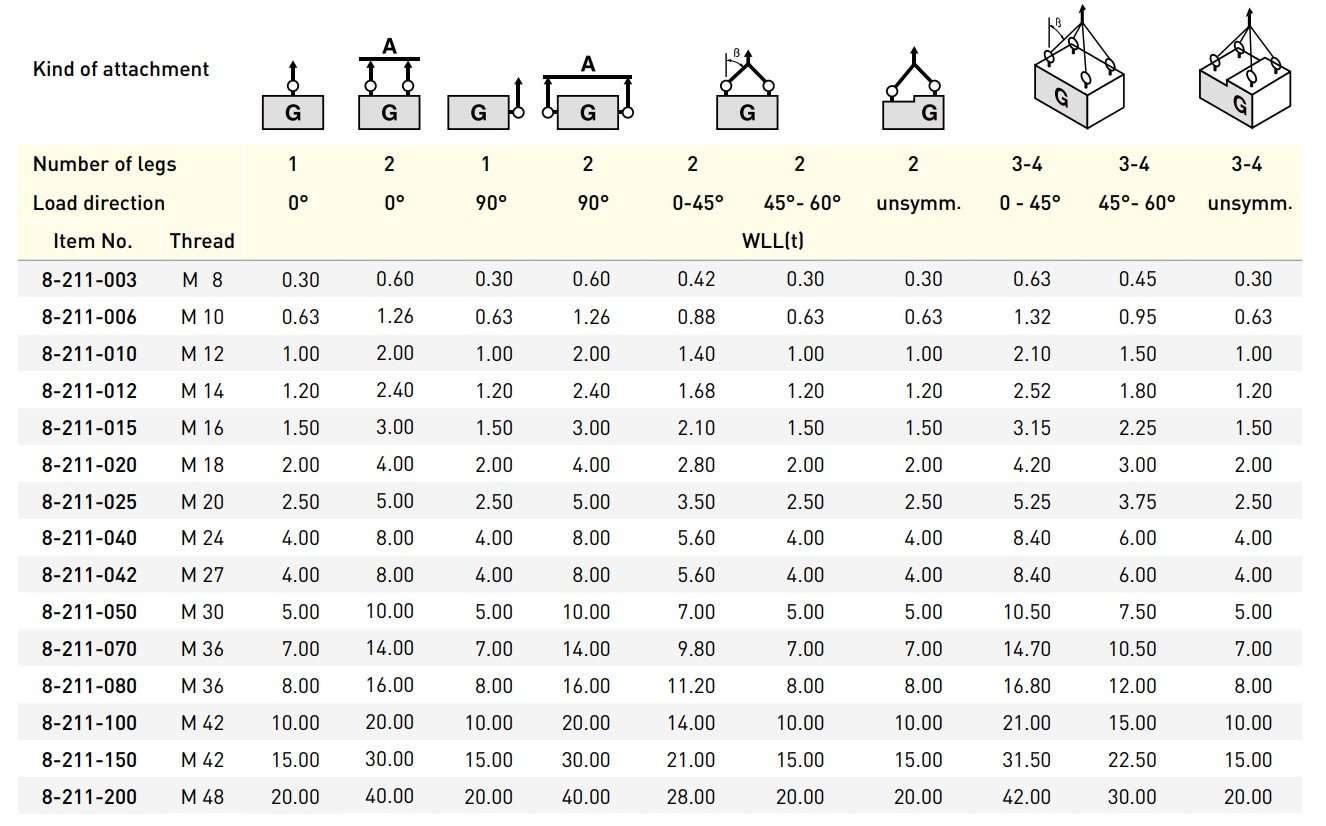

Individually proof tested to 2.5 times the WLL.

Fatigue rated to 1.5 times the WLL.

Quick and simple assembly, just a tapped hole is required."

- Features: Built-in RFID/NFC chip

- Material: Alloy steel, quenched and tempered

- Marking: According to standard, CE-marked, WLL, size, steel quality, manufacturer ID and traceability

- Temperature range: -40° up to +200°C (without reduction in WLL)

- Finish: Painted

- Standard: EN 1677-1

- Note: Longer bolts also available.

- Safety factor: 4:1