Lifting and rigging operations demand a comprehensive understanding of safety measures, especially regarding fall protection systems. Ensuring the well-being of workers and safeguarding against potential hazards is paramount to any industry involving elevated workspaces. Here, we delve into the different types of fall protection systems, offering insights and guidance for businesses in the lifting and rigging sector.

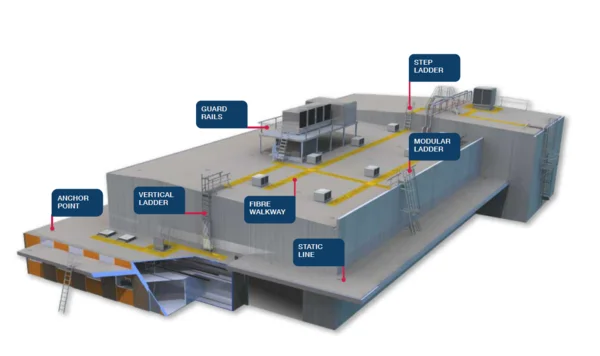

Guardrail Sytems: Widely utilised in construction and industrial settings, guardrail systems act as a physical barrier along exposed edges, preventing accidental falls. These passive fall protection systems offer a solid barricade, enhancing safety for workers at heights.

Personal Fall Arrest Systems: Comprising anchor points, full-body harnesses and connecting devices like safety lanyards, PFAS are active fall protection measures. In the event of a fall, these systems engage, effectively arresting the descent and minimising impact on the worker.

Statis Lines: With fixed horizontal or vertical cables secured between anchor points, static lines allow workers to move safely along elevated surfaces. These systems are crucial for tasks that require continuous access to specific areas at height.

Modular Ladders: Modular ladders are designed with fall protection features like guardrails and integrated ladder safety systems, providing safe vertical access. They ensure secure ascent and descent for workers accessing elevated workspaces.

Anchor Points: Essential components of various fall protection systems, anchor points are a secure attachment location for lanyards, lifelines and other personal protection equipment. They are strategically placed to ensure reliable support and stability.

Safety Lanyards: An integral part of PFAS, safety lanyards connect the worker's full-body harness to the anchor point or static line. They offer flexibility and shock-absorption capabilities, limiting the impact of force during a fall.

In alignment with Australian safety standards, such as AS/NZS 1891, lifting and rigging companies must prioritise regular inspection, maintenance, and worker training to utilise fall protection systems correctly. Compliance with these standards is essential to ensure a safe working environment and mitigate fall-related hazards.

Fall protection systems are tailored to each work environment's specific needs and risks. Employing a combination of guardrails, PFAS, static lines, modular ladders, anchor points and safety lanyards enables comprehensive coverage, minimising the potential for falls and promoting a safer workplace for all involved.

Investing in appropriate fall protection systems is a crucial step toward ensuring the safety and well-being of workers engaged in lifting and rigging operations in Australia. Prioritising safety measures demonstrated a commitment to upholding industry standards and fostering a secure work environment. Remember, elimination is always the first step to consider to reduce hazards and risks. It is always best to eliminate the fall hazard with other means if practicable (Eg. scaffolding, mechanical access, working in restraint) than to prioritise working where the risk of a fall is possible.

Contact us for more information about fall protection systems, inspections and training

Fall Protection Regulations and Standards

Improve your understanding of the Australian Regulatory Framework for fall protection.

Fall Protection Training

Explore the significance of comprehensive training and education for fall protection.