Transportation of goods demands meticulous attention to load securing to ensure safety and prevent potential hazards. It is impossible to overstate the significance of secure load transportation in lifting and rigging. Whether across short distances or traversing extensive routes, employing best practices for load securing is paramount for a seamless and safe journey. Let's delve into some essential guidelines and practices to uphold during load transportation.

Understanding the Load: Before embarking on any transportation endeavour, comprehending the nature of the load is fundamental. Weight, shape, dimensions, and fragility are pivotal in determining the appropriate securing methods. Take time to assess the load and strategise the securing process accordingly.

Choosing the Right Equipment: The appropriate securing equipment is critical, ensuring high-quality straps, chains, binders, or nets suited for the load's characteristics. Ensure these tools comply with industry standards and are in optimal condition before usage.

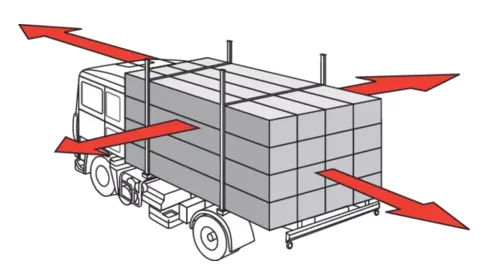

Strategic Placement and Balance: Proper distribution and balance of the load within the transporting vehicle are crucial. Centre the load and secure it firmly to prevent shifting during transit. Distribute weight evenly to maintain vehicle stability and avoid overloading.

Tension and Tightening: When securing the load, apply appropriate tension to the securing devices. Achieve optimal tension without over-tightening, ensuring a firm hold while avoiding damage to the load or the securing equipment.

Continuous Training and Awareness: Provide comprehensive training to load securing and transportation personnel. Emphasise the importance of adhering to safety protocols and staying vigilant throughout transportation. Load restraint guides, such as those from the National Transport Commission and VicRoads, are available to help ensure your load is secure and safe.

Regular Inspection and Maintenance: Inspect securing equipment for signs of wear, tear, or damage. Ensure all components are in proper working condition before each transportation operation. Promptly replace any compromised or worn-out parts to maintain safety standards.

Compliance with Regulations: Adhere strictly to local and national regulations governing load securing during transportation. Stay updated with regulatory changes and ensure full compliance to avoid penalties and, more importantly, ensure the safety of the transportation process.

Secure Attachment Points: Identify and utilise sturdy attachment points on the vehicle or trailer for securing the load. Avoid attachment to weak or unstable areas that may compromise the load's stability during transportation.

Effective load securing during transportation is fundamental to safe lifting and rigging operations. Implementing these best practices, prioritising meticulous planning, utilising proper equipment, and staying vigilant throughout the process can significantly mitigate the risks associated with transportation.

At CERTEX Lifting, we prioritise safety in lifting and rigging operations. Our commitment extends to educating and empowering our clients and partners with knowledge to ensure safe and secure transportation practices. Contact us to learn more about our safety-focused solutions tailored to your transportation needs.

Choosing The Load Securing Correct Equipment

A comprehensive guide to selecting the correct equipment for effective load securing.

Load Securing Maintenance and Inspection

Guarantee safety and integrity of the transportation process.