In the world of lifting and heavy rigging, steel wire ropes stand as an indispensable tool. These robust and versatile components play a crucial role in various industries, from construction to maritime operations. Understanding the technical specifications of steel wire rope is fundamental for their optimal usage and safety in diverse applications.

Composition

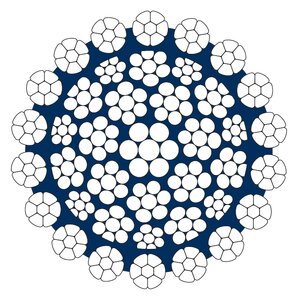

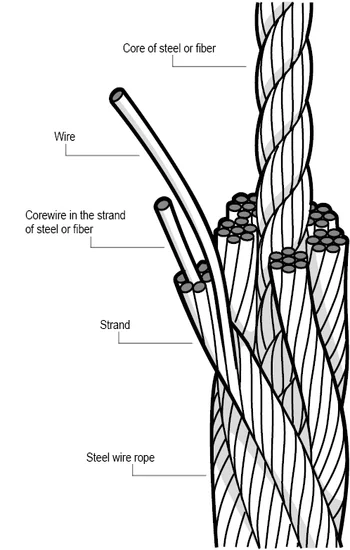

Steel wire ropes are composed of multiple strands twisted or braided together, providing strength and durability. Each rope consists of three main components: the core, strands and wires. The core provides stability and support to the strands, which, in turn, hold the individual wires.

The Strand

The strand is built up by individual wires which are laid around the core in one or more layers, typically to one of the following constructions:

- Single Lay Strand: A strand that contains only one layer of wires.

- Seale (S): Parallel lay wires - different size, same number of wires in outer and inner layer.

- Warrington (W): Parallel lay wires - the outer layer of wires has two different sizes, twice as many outer wires as inner wires.

- Warrington-Seale (WS): Parallel lay wires - a combination between Seale and Warrington, with three or more layers of wire.

- Filler wire (F): Parallel lay wires - twice as many outer wires as inner wires, with small wires to fill the spaces between the large wires.

- Compacted strand: A strand that has been formed through compaction maintaining the steel area whilst increasing the fill factor.

Materials

The primary material used in steel wire ropes is high-quality steel, renown for its robustness and tensile strength. Different grades and types of steel, including glavanised or stainless steel, cater to specific applications. Galvanised steel ropes offer enhanced corrosion resistance, ideal for outdoor or marine use, while stainless steel ropes provide durability in harsh environments.

Application

Steel wire ropes are used across a wide spectrum of industries, including construction, mining, maritime and material handling. Understanding the technical details helps in selecting the right rope for specific tasks, ensuring safety and efficiency in lifting and rigging operations.

Specifications

The technical specifications of steel wire ropes encompass various parameters, including diameter, construction type, and the number of strands and wires. The diameter influences the rope's strength and load-bearing capacity, while the construction type dictates flexibility and resistance to bending fatigue.

Maintenance

Regular inspection and maintenance are critical for ensuring the longevity and safety of steel wire ropes. Periodic checks for wear, corrosion, and damage, along with proper lubrication and storage, contribute to extending the rope's lifespan and maintaining optimal and safe performance.

In essence, comprehending the technical intricacies of steel wire ropes is pivotal for their effective utilisation. Whether for heavy lifting, rigging or industrial applications, a detailed understanding of these ropes' specifications empowers users to make informed decisions, ensuring safety and efficiency in operations. To speak to one of our steel wire rope experts, contact us today.