Steel wire ropes serve as fundamental components across a spectrum of industries, offering critical support in lifting, rigging and material handling operations. Choosing the appropriate steel wire rope involves several crucial considerations, each impacting performance, safety, and efficiency in various applications.

The selection of a suitable wire rope is primarily governed by practical knowledge and experience, and the original equipment manufacturer (OEM) or a competent person should always be consulted before selecting a wire rope suitable to the application

1. Application and Usage

Understanding the specific task and its requirements is paramount. Whether its lifting heavy loads, securing cargo, or supporting structures, different applications demand ropes with varying strengths, flexibility and durability.

2. Load Capacity and Working Conditions

Determining the expected load capacity and the working environment's conditions is crucial. Factors like the weight to be lifted, operational temperatures, exposure to chemicals, abrasion or moisture influence the choice of rope material and construction.

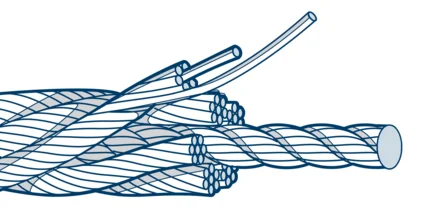

3. Rope Diameter and Construction

The diameter and construction type of the wire rope significantly impacts its strength and flexibility. Assessing the correct diameter in correlation with the load-bearing capacity ensures safety and optimal performance. The rope specifications must be compatible with any rigging system's drums, sheaves, or terminations. Failure to identify this compatibility can result in decreased rope life and potentially catastrophic failure.

4. Materials and Coating

Consider the material composition - whether galvanised, stainless steel, or other variants - based on environmental conditions and corrosion resistance requirements. Additionally, coatings like galvanisation or lubrication can enhance durability and protection against wear and tear.

5. Configuration and Design

The wire rope's configuration, such as the number of strands, wires per strand, and construction types determines flexibility, bending fatigue resistance, and load-bearing capabilities. Choosing the right configuration aligns with specific usage needs.

6. Maintainance and Longevity

Regular inspection, maintenance and proper care are essential for extending the lifespace of the wire rope. The inspection frequency of wire ropes depends on the regularity of the rope's usage and other factors.. Our wire rope technicians can provide expert advice based on thousands of hours of visual inspection experience to help create the best-tailored maintenance schedule for your wire ropes.

With visual inspections, as well as the option of our high-tech Magnetic Rope Testing (MRT) service, we can store all your inspection data and certification to ensure you know the progress of your rope life and significantly reduce the chances of any unexpected downtime.

Ensure adherence to maintenance schedules, lubrication practices, and timely replacements to guarantee optimal performance and safety.

Carefully considering these factors ensures the selection of the most suitable steel wire rope for your intended task. By understanding the application, environment, and load requirements and adhering to maintenance practices, you can ensure your operations' safety, efficiency, and longevity.

Have more questions?

Installing Steel Wire Rope

Learn how to to install steel wire rope for optimal performance, longevity and safety.

Technical Description of Wire Rope Slings

Learn about the configurations and applications of steel wire rope slings.