When lifting and rigging, the effectiveness of load securing isn’t solely reliant on robust equipment; it’s equally dependent on two fundamental yet often underestimated forces: friction and tension. Our Know How will unravel the crucial roles of friction and tension in the art of maintaining stable and secure loads during transportation.

The Significance of Tension

The Significance of Tension

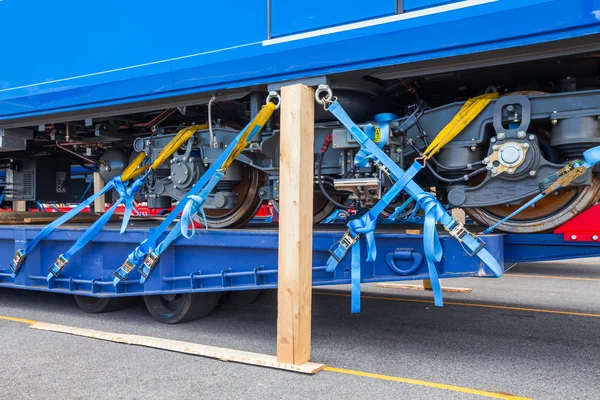

Tension refers to the force applied to stretch or tighten securing materials, which is crucial for load stability:

- Maintaining Integrity: Proper tension ensures that securing equipment remains taut and securely holds the load in place, preventing slack that could lead to movement.

- Uniform Distribution: Even tension distribution across securing materials, such as straps or chains, maintains load balance and minimises stress concentration points.

- Resistance to External Forces: Adequate tension helps the load withstand external forces encountered during transportation, such as sudden movements or vibrations.

The Force of Friction

The Force of Friction

Friction is a force that resists relative motion between surfaces in contact. In load securing, friction plays a pivotal role:

- Surface Contact: Substantial surface contact between the load and the securing equipment, such as straps or ropes, maximises friction. Increased contact enhances the grip and stability of the load.

- Preventing Movement: Adequate friction prevents the load from shifting or sliding during transportation, ensuring stability and reducing the risk of accidents.

- Surface Conditions: Surface texture, material, and cleanliness influence friction. Smooth surfaces require additional gripping mechanisms, while rough surfaces can aid in natural friction.

Achieving the Balance

Achieving the Balance

Balancing friction and tension is an art in load securing:

- Optimal Grip: Finding the sweet spot where friction provides sufficient grip without impeding tensioning is crucial for stability.

- Correct Tensioning: Proper tension when securing materials ensures they remain firm and stable without causing undue stress on the load or the equipment.

- Surface Interaction: Understanding how different surfaces interact with securing materials helps adapt and maximise friction.

At CERTEX Lifting, we understand that mastering the interplay between friction and tension is fundamental to ensuring safe and reliable load securing. Our expertise lies in providing top-quality equipment and imparting knowledge and strategies for effective load securing.

Contact us today to discover how our expertise and high-quality equipment can elevate your load-securing processes, ensuring stability and safety.

Best Practices for Safe Transportation

No matter the distance, it is crucial to employ the best practices for load securing.

Choosing the Correct Load Securing Equipment

A comprehensive guide to selecting the correct equipment for effective load securing.